رسالة عبر الإنترنت

للحصول على أقل عرض أسعار مجانًا ، يرجى ملء المعلومات التالية وإعلامنا (معلومات سرية ، ليست مفتوحة للجمهور)

للحصول على أقل عرض أسعار مجانًا ، يرجى ملء المعلومات التالية وإعلامنا (معلومات سرية ، ليست مفتوحة للجمهور)

مجال التطبيق

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

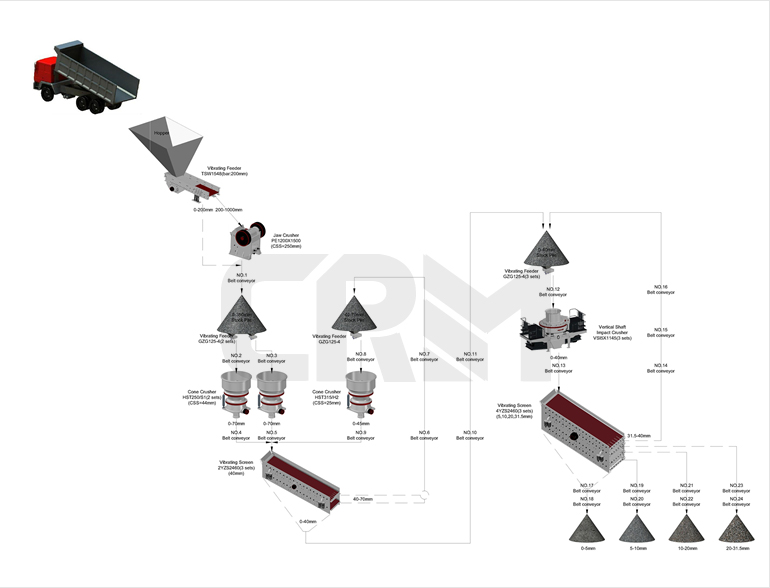

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

2021年1月1日 As the easy-to-process zinc sulphide ores are being depleted, the utilization of zinc oxide ores has attracted more and more attention (Bai et al., 2020, Luo et al.,

2014年4月1日 Future research needs on the oxide zinc mineral flotation are discussed. Abstract. In recent years, extraction of zinc from low-grade mining tailings of oxidized

2012年10月1日 In recent years, by decreasing the Zn content of the ore, the upgrade of tailing by froth flotation before acid leaching has become considerably attractive. In this

2022年7月21日 Operating Condition Recognition in Zinc Flotation Using Statistic and Temporal Correlation Features Abstract: Accurate recognition of operating conditions

2010年2月1日 To increase zinc recovery in the concentrate, this investigation performed mineralogical characterization, dispersion studies, bench and pilot-scale flotation

2021年2月4日 After lead flotation at optimum pH 8, the flotation of zinc at a different pH (5–11.5), with two collector types, was performed to study the recovery and grade of zinc

Owing to the similarities in the physicochemical and surface chemistry of the constituent minerals, separation of zinc oxide minerals from their gangues by flotation is an

2022年3月22日 Complex and non-sulfide lead–zinc ores are difficult to concentrate, but the growing demand for lead and zinc metals necessitated their beneficiation. Froth flotation

2024年3月12日 Zinc extraction from oxide ore has been paid more and more attention to due to the exhaustion of zinc sulfide ore resources. In this work, the volatilization kinetics

Flotation froth image deblurring is of great significance to research on zinc flotation working condition recognition and fault diagnosis. A blurry froth image includes not only the

2016年4月27日 Lead and Zinc Pb-Zn Separation Process Circuit. Primary Washing and Crushing. A Drag or Conveyor is used to bring the dump material to a Revolving Trommel Screen which discards all plus 2″

2013年9月23日 des travaux ont été entrepris pour examiner le rendement de colonne de flottation en regard de la récupération du zinc dans la fraction fine. Plus spécifiquement, les objectifs du travail étaient: 1. d'obtenir des données de récupération de zinc par flottation en colonne sur quatre

Description. First draft prepared by B. Simon-Hettich ... [et al.]. Published under the joint sponsorship of the United Nations Environment Porgramme, the International Labour Organisation, and the World Health Organization, and produced within the framework of the Inter-Organization Programme for the Sound Management of Chemicals.

2016年1月1日 Decreasing the CN/Zn ratio to 2 led to a significant decrease of Au recovery to 66.4% after 3 min flotation and 71.4% at the end of flotation. In the presence of zinc cyanide with CN/Zn ratio being either 4 or 2, pyrite was still completely depressed as observed in the presence of free cyanide.

2023年9月29日 Zinc oxide minerals (primarily smithsonite and hemimorphite) are important sources of Zn. Flotation is the most widely used method of enriching zinc oxide minerals for mineral processing. Chelating reagents have received extensive attention for the flotation of zinc oxide ores because of their high selectivity and stability. This paper systematically

2022年3月22日 Complex and non-sulfide lead–zinc ores are difficult to concentrate, but the growing demand for lead and zinc metals necessitated their beneficiation. Froth flotation is practically the most effective method in their beneficiation when optimum flotation conditions are attained. The aim of the current study is to use process mineralogy as a tool to

2021年11月1日 The feed ore of zinc oxide ore flotation process was the underflow of the hydrocyclones, and the flowsheet of industrial tests of zinc oxide ore flotation is shown in Fig. 8. The industrial tests were carried out for 17 days (from June 7, 2017 to June 23, 2017) for a total of 38 work shifts, and the cumulative results of industrial tests are ...

2006年11月1日 The removal of heavy metals from dilute aqueous solutions (in the range of 10 −7 –10 −4 mol dm −3) is often not acceptable using classical methods, which do not achieve levels in accordance with environmental quality standards.Electroflotation has certain desirable characteristics, compared to dissolved and dispersed air flotation,

2017年10月1日 Thus, this research was performed to describe the behavior of important factors affecting the leaching of zinc from a tailing sample obtained from lead-zinc flotation circuit in ferric sulphate and sulfuric acid media. It was found that 0.5 mol L −1 ferric sulphate is enough to dissolve both oxidized and sulphidic minerals. Response surface ...

2024年3月12日 Zinc extraction from oxide ore has been paid more and more attention to due to the exhaustion of zinc sulfide ore resources. In this work, the volatilization kinetics of Zn from the flotation products of low-grade lead–zinc oxide ore during carbothermal reduction in the temperature range of 900–1300 °C were investigated. The phase

Zinc rougher is the first flotation cell of the zinc flotation, and thus its flotation performance is influenced by the fluctuations of feed grade. As shown in Fig. 1 , the feed is directly input to the zinc rougher, in which zinc mineral is separated by the hydrophobic differences between zinc mineral and other mineral particles ( Tian, Tang ...

2000年12月1日 A significant increase in grade and recovery of the products obtained by zinc flotation at pyrite depression can be achieved by acting upon pulp airing, the pH conditions and the quantities of reagents added during flotation. Resume - L'usine de traitement Chaabat-El-Hamra traite un minerai sulfure de blende et de pyrite.

This is explained by the fact that complete deposition of zinc ions occurs only at pH = 8 [24]. Thus, at pH 8 oxide, hydroxide ...

La gangue est flottée avec la sphalérite attachée aux résidus. Télécharger le PDF >. Les collecteurs Danafloat™ suivants sont les plus pertinents pour la flottation du plomb-zinc. Flottation sélective du Pb: Danafloat™ 067. Danafloat™ 068. Danafloat™ 070. Danafloat™ 271, 571 pour le plomb terni ou oxydé. Flottation sélective ...

2019年7月22日 With the continuous depletion of a large number of zinc sulphide ores that are easy to treat, the finely disseminated and refractory low-grade zinc oxide ores has become an important source for the production of zinc minerals. In this paper, a sulfurization-amination flotation process has been proposed for concentrating large

2024年3月1日 In the lead-zinc flotation process, airflow is rarely adjusted. Additionally, due to challenges in equipment maintenance, there are generally no sensors directly measuring froth depth, feed flow rate, and feed particle size distribution. The addition of reagents is the main operation in the lead-zinc flotation plant, and the amount of reagent ...

2021年8月18日 ABSTRACT. Pilot scale flotation tests (maximum capacity 1 mt h −1) on refloating smithsonite from sulphide flotation tail using cyclonic static microbubble flotation column (FCSMC) were carried out at the Wulagen Mine site.FCSMC is easy to install and operate, ideal for pilot tests. Condition (optimisation) tests were carried out first to verify

2022年7月21日 Accurate recognition of operating conditions helps to correctly control froth flotation. Most previous recognition methods mainly focus on the statistic feature but ignore the temporal information in the dynamic and changing flotation process. Actually, the temporal changing trend of froth appearance can reflect the change in flotation

2024年2月29日 Lead flotation tailings were used as the feed ore for the zinc flotation tests. The effects of different types of reagents on the zinc flotation indices were investigated, the flotation process is shown in Fig. 12 and the results of each reagent test are shown in Fig. 13. Download : Download high-res image (136KB) Download : Download full-size ...

Flotation froth image deblurring is of great significance to research on zinc flotation working condition recognition and fault diagnosis. A blurry froth image includes not only the air–water fogs and dust produced in industrial sites, but also motion blur caused by camera vibrations. However, due to the redundancy and complexity of froth images, obtaining satisfactory

سابق: الة طحن الخضر و الفواكه

التالي: طاحونة العمود المرفقي فولكام

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:cywaitml@gmail.com