The Diferent Parts Of Cement Mill

مجال التطبيق

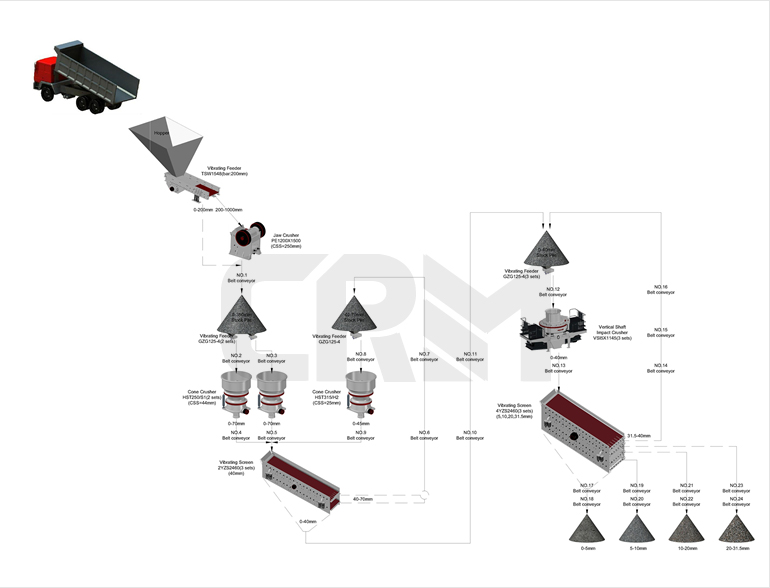

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

What Are the Parts of a Cement Mills?

2023年8月23日 To achieve this crucial transformation, a cement mill comprises several intricate parts, each serving a distinct purpose in the grinding and processing operations. Let’s delve into the essential components that make up a cement mill.

The cement mill - Understanding Cement

Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the motion of the

Cement manufacturing - components of a cement plant - Understanding Cement

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the

Review on vertical roller mill in cement industry its

2021年1月1日 There are three types of cement manufacturing processes - wet, semi-dry and dry processes. In the wet/semi-dry process, the raw materials are produced by

EVERY COMPONENT OF BALL MILL DETAILED EXPLAINED - INFINITY FOR CEMENT ...

Elements of Ball Mill – Overview. Mill Drive Concepts. Example Planetary Gear Drive. Planetary gear reducer concept MAAG. -Two gear stages with three planets. -All shafts

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry: cement ball

Cement Finish Milling (Part 1: Introduction History)

2019年12月2日 Introduction. Cement is manufactured by heating a mixture of ground limestone and other minerals containing silica, alumina, and iron up to around 1450 C in

Prediction of cement specific surface area in the cement mill

2022年4月25日 Prediction of cement specific surface area in the cement mill grinding process: A method combining dual-frequency principal component analysis and extreme

Cement Manufacturing Process - The Engineering Community

2018年8月28日 When material reaches the lower part of the kiln, it forms the shape of clinker. CEMENT MANUFACTURING PROCESS PHASE V: COOLING AND FINAL

MECHANICAL ELEMENTS OF TUBE MILLS - INFINITY FOR CEMENT EQUIPMENT

The external parts of a standard tube mill consist of mill shell, mill heads, mill bearings, feed and discharge equipment and include also the mill drive. In the following the external

Everything you need to know about

1) alite size, as before. 2) C2S content , as before. 3) grinding aid. Cost 0.6-1.2 €/t, usage 150-400 g/t. As the cement particle gets smaller the pores disappear and no longer become a factor. Increasing the amount of

Cement Mill Optimization: Practical Strategies for

Adjusting mill parameters: Fine-tuning mill parameters such as mill speed, ball charge, filling ratio, and grinding media size can have a substantial impact on the grinding efficiency of the mill. For example, a 10%

5 Must-know Ball Mill Parts And Functions AGICO Ball Mill

The ball mill cylinder is a hollow barrel, which is rolled and welded by several steel plates. The two ends of the cylinder are connected to the ball mill trunnion with end covers. As the main part of the ball mill, it has to bear the weight of the lining plate, grinding media, compartment plate, and grinding materials.

Review on vertical roller mill in cement industry its

2021年1月1日 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity. Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550–600 million

The Decision Algorithm of Cement Mill Operation Index

2023年1月25日 Abstract An improved differential evolutionary cement mill operation index decision algorithm based on constraint control and selection strategy is proposed to address the problem that the operation index is usually decided by manual experience in the cement mill operation process, which causes unqualified cement specific surface area and

OK™ Raw and Cement Mill - FLSmidth

Smart vertical roller mill design for raw, cement and slag grinding. The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between ...

Cement Milll Separator Cyclone Air Separator in Cement Plant

Product Name: cement mill cyclone air separators. Capacity: 10 – 250 TPD. Condition: brand new. Airflow: 16000 – 240000 m3/h. SEND INQUIRY. Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants. The function of the separator is to separate ...

Vertical roller mills FLSmidth Cement

OK™ Raw and Cement Mill. Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement ...

Parts of Vertical Roller Mill - INFINITY FOR CEMENT

Vertical Roller mills. Vertical Roller mills Main parts of a vertical roller mill Mill body feed Hydraulic system Nozzle and retention ring mill body seperator Vertical roller mill: frame type Polysius: Polroll Gbr. Pfeiffer: MPS Vertical roller mill: rocker arm type Loesche: LM Kobelco: OK Processes inside a vertical roller mill Grinding

The segregation of cement clinker particles in a mill-feeding

2023年8月1日 Cement is widely used in the construction of infrastructures such as buildings, bridges, and roads. The production of cement is a complicated chemical and bulk solid handling process, and every link in its manufacturing process has a great impact on production [1].One of the most energy-consuming processes is the grinding of cement

Effect of grinding aids in the cement industry, Part 2

2001年1月1日 ASTM C465 Standard Specification for GAs related such changes to cement flowability and mill retention time (MRT) during grinding [17]. The MRT can be defined as the average time necessary for the ...

Utilization of Basic Oxygen Furnace (BOF) slag in the

2006年5月1日 The hydration characteristics of any hydraulic binder like cement depend upon the microstructure and morphology of the phases in the binder. During cement manufacture, a liquid of binary composition of CaO-74% wt and SiO 2-26% wt, on fast cooling from 1250 °C, form C3S and β C2S and free lime. However, the Treated slag

quadropol® thyssenkrupp Polysius Grinding Technologies

The request for interchangeable parts for the three mills was fulfilled and represents still a holistic approach. For coal grinding a QMK² 32/16 completed the grinding portfolio. The cement mills are equipped with high efficiency separators to achieve cement qualities with a fineness up to 5 000 cm2/g acc. to Blaine.

13 Types of Concrete Mixer Machines You Need to Know

2024年4月18日 13 Types of Concrete Mixer Machines You Need to Know. Raas Sarker Tomal. Concrete is the most familiar building element. The densest and strongest concrete is that in which cement paste fills the voids with the sand and the resulting mortar fills the voids in the coarse aggregate. Every grain of sand should be entirely coated with cement.

Separators in the cement industry

2018年7月1日 The main separating device is a cylindrical rotor. The rotor is like a cage composed of blades closely spaced. The rotor is operated by a variable speed drive. The rotor speed determines swirl in the classifying zone and therefore the cut of the separator. The material is generally fed at the top of the separator.

parts of ciment mill

The Diferent Parts Of Cement Mill - artisjokkoken. The Diferent Parts Of Cement Mill. The diferent parts of cement millrocess diagnostic studies for cement mill 9in both the chambersoth the chambers of the cement mill were charged with 80 of the designed charge, which works out to 86 t in ist chamber and 172 t in the iind chamberhe mill is ...

Cement Manufacturing Parts Applications Jodat Tech

Company Name. 115 Cedar Street. Cassandra, PA. 15925. (814) 659 - 9929. jodatt@yahoo. Jodat Tech is committed to enhancing your cement plant operations with quality, innovative, and efficient cement manufacturing parts. Contact us today!

Mills 101: Everything You Need to Know About Different Types of Mills

Here are some common types of mills: 1. Flour Mills. Flour mills are used to grind grains into flour. They are essential in the production of various food products, such as bread, pastries, and pasta. Flour mills can be powered by different energy sources, including electricity, water, or wind. 2.

MAINTENANCE IN THE CEMENT INDUSTRY

Maintenance is often the largest controllable operating cost in the cement industry and hence a critical business function. Maintenance should be regarded in best practice organizations not simply as a cost to be avoided but, a department that control the assets of the company with well organize reliability engineering to a high leverage ...

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت